A bottle oven or kiln is a brick-built, bottle-shaped structure in which pottery, or its component materials, were fired.

The simplest type of bottle oven - the updraught hovel oven - consists of two main parts:

1) The Hovel

The outer part is known as the hovel. All hovels had one distinctive and common feature, the bottle shape. This shape, with its wide base and narrow neck, evolved to accommodate the firing chamber together with room for men, materials and equipment. The tapering chimney was better for creating draught which aided the firing process and helped to take away smoke. It also improved protection from bad weather. In order to take away the thick black smoke created during firing, Local Byelaws, passed in 1877, stated that hovels should be not less than 60 feet high. Some could be up to 70 feet (21m) high.

|

| Hovel bottle oven at Gladstone Pottery Museum Longton, Stoke-on-Trent Photo: unknown source Date: 2019 |

2) The Firing Chamber

This is the inner part of the bottle oven. It is a cylindrical structure with a domed roof. Its walls are about 12" (30cm) thick. The domed roof is called the crown. Iron bands, known as bonts (or bontings), run right round the chamber at about 12" (30cm) intervals to strengthen the brickwork as it expands and contracts during firing.

|

| Bonts surround the oven to give it strength Fixing brackets and bolts ensure a good tight fit Photo: Terry Woolliscroft Collection Date: 2018 |

The doorway to the chamber, is called the wicket. For the most common ovens it is just about tall enough for a man with a saggar balanced on his head to pass through. Some specialist ovens, such as those which can be seen at the Acme Marls factory at Bournes Bank, Burslem, were only tall enough just for the man to pass through, without the saggar. These ovens were used for firing refractory products, such as kiln furniture, which was carried into the kiln at waist height. The wicket is surrounded by a stout cast iron frame.

|

| Height of the standard wicket - tall enough for a man with a saggar balanced on his head Seen here - Jim Evans, the fireman at W.T.Copeland, Stoke |

Around the base of the firing chamber are firemouths (the exact number depends on the size of the oven) in which coal fires were lit for the firing. Inside the oven there is a small chimney, called a bag, over each firemouth. The bags carried hot gases and intense heat from the fire into the oven's interior. Flues underneath the upwardly sloping floor of the oven, leading from each firemouth, distributed the heat throughout the inside. In the centre of the oven floor is the well hole.

Each bottle oven had its own 'character' and firemen had to learn how best to work with them and to control the way they performed and fired.

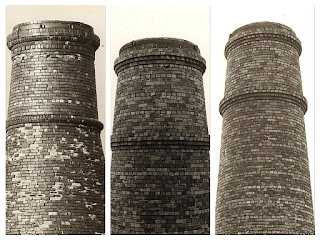

No two bottle ovens or bottle kilns were (and are) alike. They were all built differently, many without any architects' drawings or plans. Many were built 'by eye' and based only on the experience of the oven builder and the requirements of the factory owner. 'They just went up'. The decorative brickwork at the top of the hovel varied on the whim of the builder and owner and may have been a kind of trademark.

CONSTRUCTION OF UPDRAUGHT BOTTLE OVENS at Twyfords Etruria Works in 1921

Images of the construction of updraught bottle ovens at Twyfords sanitary earthenware factory in Etruria, near Hanley, Stoke-on-Trent

| Bottle oven construction at Twyfords Etruria Date: February 1921 |

| Bottle oven construction at Twyfords Etruria Date: 1920s |

| Bottle oven construction at Twyfords Etruria Date: 1920s |

| "Twyfords Ltd. Hanley. New Earthenware Pottery View of Ovens" Date: 1920s |

CONSTRUCTION OF A MUFFLE KILN at Twyfords Fireclay factory, Cliffe Vale, Stoke-on-Trent in the 1920s

Fireclay products for use in bathrooms are, by their very nature, very large and very heavy. A fireclay bath for instance needed to be hauled around the factory by a team of men with trolleys, ropes and pulleys.These huge pottery products could not, therefore, be fired in a conventional bottle oven using saggars to protect them from the flames and products of combustion of the coal. No saggar was big enough!

Fireclay products such as baths, mortuary slabs, sinks and urinal stalls, needed to fired in a large muffle kiln. Here the product was stacked in a chamber which was kept sealed and away from the flames and smoke of the burning coal.

These photos show the construction of a huge new muffle kiln, for firing fireclay sinks, baths and urinals at the Twyfords factory, Shelton New Road, Cliffe Vale, Stoke-on-Trent. Now demolished.

| Construction of fireclay muffle kiln Twyfords Date: 1920s |

| Construction of fireclay muffle kiln Twyfords Fireclay factory, Cliffe Vale, Stoke-on-Trent Date: 1920s |

CONSTRUCTION DRAWINGS - CROWN WORKS, STEVENTON PLACE, BURSLEM

Possibly an 'updraught skeleton bottle oven' more here>This oven was surveyed in the Bottle Oven Survey more here>

Demolished, late 1970s.

| Crown Works, Steventon Place, Burslem. Building cross sections of the bottle oven Courtesy of Staffordshire Past Track here> date: 1982 |

THE PERMISSIBLE HEIGHT OF BOTTLE OVEN CHIMNEYS

The following comes from the (hand-written) Borough of Hanley Committees’ minutes, stored in the Staffordshire Archives, Hanley Library, Bethesda Street, Stoke-on-Trent.Works Committee Minutes – 14 February 1877

Height of Chimneys - Resolved

That the following Regulations in force under the late Bye-Laws be re-enacted pursuant to Miscellaneous Bye Law No 3, viz:

- That the Chimneys of all Mills, Engines, Slip Kilns, and Manufactory

OvensHovels be not less than 60 feet high. - That all Hardening and Enamel Kilns, Fret Kilns, and Colour Kilns, be in Hovels, or have Chimneys not less than 40.5 feet high.

- That all public Bread Ovens, and Brick Ovens, or Kilns, or Brick Sheds, must have Chimneys not less than 40 feet high.

- That no Brick Clamps be erected or fixed

Extract taken by Paul Niblett, January 2014

MODIFICATIONS for the WAR EFFORT, DURING THE SECOND WORLD WAR

The curious caps on the top of the bottle oven stacks shown in this photograph were 'baffles' constructed on the top of ovens during WWII. The caps were on stilts above the opening of the stack so as to allow the free passage of combustion gases from the oven. The baffle or cap masked the glow from the burning coal below and prevented ovens (being fired) from being seen by visiting enemy bombers.| Bottle Ovens - construction. Caps built over the top of bottle oven stacks to hide glow in firing Source: 'Potbanks' YouTube here> Possibly Middleport Factory Date: early 1950s |

FIREMOUTH TYPES

The design of the firemouth for a potters' updraught or downdraught bottle oven could either be :

A) With a vertical feed hole, with 2, hinged, cast iron firedoors

B) With a vertical feed hole, with 2 sliding fireclay slabs

C) With a horizontal hob-mouth feed hole, with sliding fireclay slabs

B) With a vertical feed hole, with 2 sliding fireclay slabs

C) With a horizontal hob-mouth feed hole, with sliding fireclay slabs

A. Vertical feed hole, hinged firedoors

This type is the most common now found on the remaining bottle ovens in Stoke-on-Trent. Firemouths were built into the side of the oven. They each have a vertical feed hole where coal is baited (shovelled) onto the fire bed. The hole can be closed off, partly or fully to regulate the flow of air to the fire, by means of two hinged cast-iron doors suspended from robust ironwork surrounding the firemouth. Good examples of this type of firemouth can be see at Gladstone Pottery Museum, Longton, or Moorcroft Pttery, Cobridge .

|

| Vertical firemouth, vertical feed hole, firedoors open Last Bottle Oven Firing Cold firemouth, lumping Photo: Brian Colclough Collection Date: Aug 1978 |

|

| Vertical firemouth, vertical feed hole, firedoors open Last Bottle Oven Firing Cold firemouth, lumping Photo: Brian Colclough Collection Date: Aug1978 |

|

| Vertical firemouth, vertical feed hole, firedoors open Last Bottle Oven Firing Just after peak firing Photo: Brian Colclough Collection Date: Aug 1978 |

|

| Vertical firemouth, vertical feed hole, firedoors closed Last Bottle Oven Firing Photo: Brian Colclough Collection Date: Aug 1978 |

B. Vertical feed hole, no hinged firedoors, with vertical sliding fireclay slabs

This type can be found on some of the remaining bottle ovens in Stoke-on-Trent. Firemouths were built into the side of the oven. They each have a vertical feed hole where coal is baited (shovelled) onto the fire bed. The hole can be closed off, partly or fully, to regulate the flow of air to the fire, by means of 2 vertical slabs of fireclay resting on the brickwork of the firemouth. Examples of this type of firemouth can be see on the bottle ovens at Middleport Pottery, Middleport. Compared with the firemouth with cast iron doors, this type of firemouth would have been cheaper to construct but perhaps a little more difficult to operate.

|

| Vertical firemouth, vertical feed hole, no firedoors Fireclay slabs missing Middleport Pottery, Middleport Photo: courtesy Jason Adams Date July 2023 |

|

| Brief explanation of the use of either firedoors or fireclay slabs to close the bottle oven firemouth. from "Pottery Ovens, Fuels and Firing" by Stanley R. Hind 1937 |

|

| Vertical firemouth, vertical feed hole, no firedoors Middleport Pottery, Middleport Photo: Terry Woolliscroft collection Date: July 2023 |

C. Horizontal, hob-mouth feed hole, with horizontal sliding fireclay slabs

This type can be found on some of the remaining bottle ovens in Stoke-on-Trent. Firemouths are built in the side of the oven, to create a wide hob or 'ledge'. A horizontal feed hole is built into the hob immediately above the firemouth and fire bed. Coal is baited (shovelled) onto the fire bed. The hole can be closed off by means of loose slabs of fireclay placed or slid over the feed hole.

|

| Bottle oven with Hob Mouth Falcon Pottery, Sturgess Street, Stoke Photo taken as part of Bottle Oven Survey, 1976 Two ovens still remain on this site (2023) |

|

| Hob mouthed oven baiting Fieldings Crown Devon Pottery, Stoke Photo: Source unknown Date: 1930s |

|

| Hob mouthed oven baiting Jim Evans fireman at Spode, Stoke Photo: Source unknown Date: Unknown |

FLOOR FLUES

In an updraught bottle oven, a system of flues, running under the floor, distribute hot gases and heat from the firemouths to the centre of the firing chamber. According to Stanley Hind in his book - Pottery Ovens Fuels and Firing - the aim was to 'maintain all quarters of the oven in the same state of progress' and to 'to bring up the bottom heat with as little lag as possible behind the upper parts' so as to give a consistent 'fire'.

In a downdraught bottle oven the flue system is more complicated since hot gases passing through the setting during firing needed to travel a more complex path so as to pass as much heat as possible to the products being fired.

The design and layout of the flues varied according to the type of bottle oven - updraught or downdraught - and its overall size. Generally, flues were constructed as big as possible, depending on structural stability, to give as much air flow (heat distribution) as possible, and to make the job of controlling the oven by the fireman as straightforward as possible.

|

| Bottle oven flues Falcon Pottery, Sturgess Street, Stoke HOB-MOUTHED OVEN Photo: Terry Woolliscroft Collection Date: May 1976 taken as part of Bottle Oven Survey here> |

|

| Bottle oven construction flue plan From "Notes on the Manufacture of Earthenware" by E A Sandeman, 1901 |

CHIMNEY ORNAMENTATION

The decorative ornamentation to the top of a bottle oven chimney was influenced by practicality, the builder's preference, skill and whim, and to its location. |

| Bottle oven chimney ornamentation Photo: Terry Woolliscroft Collection Date: 1975 |

|

| Bottle oven chimney ornamentation Photo: Terry Woolliscroft Collection Date: 1975 |

|

| Bottle oven chimney ornamentation Photo: Source unknown |

|

| Bottle oven chimney ornamentation Burslem, Moorland Pottery muffle kiln Photo: Terry Woolliscroft Collection Date: July 2019 |

|

| Bottle oven chimney ornamentation Twyfords Glost Ovens, Cliffe Vale , Stoke-on-Trent Photo: Virtue, London Date: 1900 |

NOTES on the MANUFACTURE OF EARTHENWARE

Ernest Albert Sandeman 1921

Extracts from Chapter 13

"Down Draught Ovens have come largely into use for biscuit, as it is considered that they are more economical in fuel, and that they can be worked to produce a more regular heat all over the oven; they are also generally used in firing firebricks.

They are constructed in several ways, some with a chamber underneath the oven into which the down-draught flues run, and from this chamber a main flue is connected with a stack or shaft standing apart from the oven, the stack being used in common by several ovens. The flue to this stack is furnished with a door that can be opened or closed at will. The oven has also a stack like an up-draught oven, but with a damper on the crown hole that can be opened or shut by a lever.

The oven is started in the same way as an up-draught oven, but when it has sufficient heat in it the damper on the crown hole is closed and the door in the flue to the outside stack is opened, and by this means the heat is drawn down into the bottom of the oven by the flues, any surplus heat passing through the chamber to the outside stack.

The name for this class of oven should be 'up and down-draught', as the course of the draught is changed during the firing from up to down and down to up, according to the heat prevailing in the top or bottom of the oven. It must be admitted that the down-draught oven is scientifically the more correct, as the gases and air have further to travel as they pass among the bungs up to the dome and are there deflected down among the bungs again to the flues in the bottom, and the combustion is more complete.

Prima facie, this, coupled with a diminished consumption of fuel, would indicate that this class of oven is the best, but it has to be taken into consideration that the first cost of downdraught ovens is heavier, both owing to the arrangement of the flues and to the extra stack outside, and that they require far more repairs, and that these repairs are more costly to carry out than in up-draught ovens. In fact it is often difficult to locate a stoppage in a flue without pulling down a lot of brickwork; added to this, they require more attention in firing. Messrs. Minton's and Roby's patents are reckoned some of the best in this class of oven.

These ovens may also be built with a big flue instead of a dome underneath, and also, to avoid the expense of an outside stack, a wide flue may be carried up the up-draught stack outside and joined into it above the damper; but the draught obtained by this means is not sufficient, and if several ovens are to be built on the down-draught system it would probably be cheaper to build an outside stack in connection with them all, and the working results would undoubtedly be better."

More about oven types here>

BOTTLE OVEN REPAIR and MAINTENANCE

RIDDINGThis was an essential process in the life of a bottle oven. It entailed the thorough repair and relaying of the flues, oven bottoms, and bags. This was a major operation which put the oven out of use for some considerable time. It needed to be done every three years or so - depending on the work that the oven had been put to. In 1920 ridding would cost around £30.

REBUILD

A complete rebuild of a bottle oven, excluding the hovel, was required, on average, every 20 years.

Wengers Ltd.

Etruria, Stoke-on-Trent

BOTTLE OVEN & KILN BUILDERS of THE POTTERIES

F BrammerWengers Ltd.

Etruria, Stoke-on-Trent

Talbots

Hanley

Hanley

H. Howlett and Sons

Bryanswood and Boundary Street, Hanley.

"Specialists as oven and kiln builders."

Mountford

Kiln Builders

Bryanswood and Boundary Street, Hanley.

"Specialists as oven and kiln builders."

Mountford

Kiln Builders

Alfred Moore

Longton

Longton

Leonard Salmons

Longton

Longton

Burslem

Not a builder but a supplier to the trade. Iron Foundry. Known to manufacture bottle oven iron work: wicket surrounds, firemouth and door furniture, bonts.

Download pdf here>

Description courtesy of “A Pioneer Potter” by Michael Cardew

“All he needed was a supply of plain firebricks, a good fireclay mortar, and a boy to hand him the bricks. His first step was to dismantle the old dome. I expected it to collapse suddenly, more or less at a touch, but was surprised to see that he had to take it down brick by brick. Next he built himself a platform on which to stand. Then he complained that the new firebricks I had provided were wet, so we hastily found dry ones for him. Standing now on his platform he took time to prepare a good surface - a smooth circle, sloping at 45 degrees - from which to ‘spring’ the dome.

He then proceeded to lay the first two bricks lying side by side on this 45 degree slope. To my surprise, they stayed there, and did not slide or fall. He went on, laying brick after brick until the first circular course was complete, Cutting the last brick to fit tight into its space and ramming it home like the keystone of an arch. The whole circular course of bricks was now firmly locked in position and he immediately went on to the second, the third and all the other courses, which he laid in exactly the same way.

He had built so many domes that his eye was trained and he was able to dispense altogether with the trammel or guide stick. He provided for the holes at regular intervals by laying one brick ‘dry’ without mortar standing up a few centimetres above the others; when the dome was complete he went inside with a hammer and knocked out the dry-set bricks to leave holes. As the work progressed towards the centre the angle of the bricks became more nearly vertical, but since the circles were now smaller they locked each other more securely.

For the last few circles he left his platform and worked from the top, standing on his own uncompleted dome; for the last circle of all he had to cut most of the bricks to a tapering wedge shape, leaving at last a central hole about 9 inches across.”

Ordinary building bricks called 'common bricks' were used wherever little or no heat was present. So, for instance, commons were used during the building of the hovel or the stack of the oven. They were also been used for the outer wall of the firing chamber itself, away from the fierce heat of the fires. Common bricks provided sufficient strength in these areas. They were also very cheap to buy compared with heat resisting fireclay bricks. Common bricks were commonly available and local brickworks would have supplied these.

The more expensive, specialist, 'fireclay refractory bricks' were used wherever the oven was subject to intense heat. So the firemouths, glut arches and flues would be built with fireclay bricks. So too were the bags and the wall immediately above and surrounding the bags. Specialist brickworks having access to fireclay (found together with coal seams) were able to produce the specialist hard-wearing and heat resistant bricks.

Berry Hill, Stoke-on-Trent

Cobridge Brick and Marl Co. Ltd.

Cobridge

Fenton Collieries

Fenton, Stoke-on-Trent

Sneyd Brickworks

Nile Street, Burslem, Stoke-on-Trent

Fenton, Stoke-on-Trent

In the Potteries a favourite supplier of fireclay bricks was the firm of D. Duddell Ltd. Fenton.

http://www.thepotteries.org/brickworks/lane_end.htm

Sneyd Colliery Co. Ltd.

The Sneyd Colliery and Brickworks Company, Ltd.,

Nile Street, Burslem

Harris and Pearson

South Staffordshire

http://www.harrisandpearson.info/index.html

E J and J Pearson

Fire Brick Works, Stourbridge, Worcs.

Founded 1860

Manufacturer of firebricks and fireclay goods at the Delph Works, Brierley Hill, which was their main centre of operation. They also owned the Crown Works, Amblecote; and Tintam Abbey Mines and Works at Brierley Hill. The combined output of these three sites in 1903 was around three-quarters of a million firebricks per week. The company also produced speciality bricks and tiles used in the construction of pottery kilns, glass house pots, gas retorts, crucibles, linings of blast furnaces etc.(Courtesy: Graces Guide https://www.gracesguide.co.uk/E._J._and_J._Pearson)

Berry Hill Brickworks Ltd

Berry Hill, Stoke-on-Trent

Hall Brothers

(J. T. Hall Refractories)

Stourbridge.

Bonnybridge Silica and Fire Clay Co.,

Bonnybridge, (just north of Glasgow), Scotland

https://www.scottishbrickhistory.co.uk/bonnybridge-silica-and-fire-clay-co-bonnybridge/

John Stein

Castlecary Fireclay Works, Castlecary, Scotland

https://www.scottishbrickhistory.co.uk/john-gilchrist-stein-fire-bricks-of-great-importance/

The list below is courtesy http://www.thepotteries.org/brickworks/index.htm and shows 43.

Not a builder but a supplier to the trade. Iron Foundry. Known to manufacture bottle oven iron work: wicket surrounds, firemouth and door furniture, bonts.

"THE ERECTION OF OVENS AND KILNS" by Wengers Ltd.

|

| Wengers Erection of Ovens and Kilns 1937 |

BUILDING THE 'CROWN' (DOMED ROOF) of the FIRING CHAMBER

How a South Wales bricklayer did it at Winchcombe Pottery, 1930sDescription courtesy of “A Pioneer Potter” by Michael Cardew

“All he needed was a supply of plain firebricks, a good fireclay mortar, and a boy to hand him the bricks. His first step was to dismantle the old dome. I expected it to collapse suddenly, more or less at a touch, but was surprised to see that he had to take it down brick by brick. Next he built himself a platform on which to stand. Then he complained that the new firebricks I had provided were wet, so we hastily found dry ones for him. Standing now on his platform he took time to prepare a good surface - a smooth circle, sloping at 45 degrees - from which to ‘spring’ the dome.

He then proceeded to lay the first two bricks lying side by side on this 45 degree slope. To my surprise, they stayed there, and did not slide or fall. He went on, laying brick after brick until the first circular course was complete, Cutting the last brick to fit tight into its space and ramming it home like the keystone of an arch. The whole circular course of bricks was now firmly locked in position and he immediately went on to the second, the third and all the other courses, which he laid in exactly the same way.

He had built so many domes that his eye was trained and he was able to dispense altogether with the trammel or guide stick. He provided for the holes at regular intervals by laying one brick ‘dry’ without mortar standing up a few centimetres above the others; when the dome was complete he went inside with a hammer and knocked out the dry-set bricks to leave holes. As the work progressed towards the centre the angle of the bricks became more nearly vertical, but since the circles were now smaller they locked each other more securely.

For the last few circles he left his platform and worked from the top, standing on his own uncompleted dome; for the last circle of all he had to cut most of the bricks to a tapering wedge shape, leaving at last a central hole about 9 inches across.”

BRICKS

WHAT TYPES of BRICKS WERE USED in OVEN and KILN CONSTRUCTION?

Two basic types of brick were used during the construction of a bottle oven.Ordinary building bricks called 'common bricks' were used wherever little or no heat was present. So, for instance, commons were used during the building of the hovel or the stack of the oven. They were also been used for the outer wall of the firing chamber itself, away from the fierce heat of the fires. Common bricks provided sufficient strength in these areas. They were also very cheap to buy compared with heat resisting fireclay bricks. Common bricks were commonly available and local brickworks would have supplied these.

The more expensive, specialist, 'fireclay refractory bricks' were used wherever the oven was subject to intense heat. So the firemouths, glut arches and flues would be built with fireclay bricks. So too were the bags and the wall immediately above and surrounding the bags. Specialist brickworks having access to fireclay (found together with coal seams) were able to produce the specialist hard-wearing and heat resistant bricks.

COMMON BRICK MANUFACTURERS

Berry Hill BrickworksBerry Hill, Stoke-on-Trent

|

| Berry Hill Bricks Advertisement 1957 |

Cobridge Brick and Marl Co. Ltd.

Cobridge

|

| Apedale Heritage Centre, Newcastle-u-Lyme, bricks collection Date: Jan 2020 |

Fenton Collieries

Fenton, Stoke-on-Trent

|

| Fenton Collieries Brick Photo: unknown source Date: unknown |

Sneyd Brickworks

Nile Street, Burslem, Stoke-on-Trent

|

| Advertisement Sneyd Brickworks Ltd Nile St., Burslem |

FIRECLAY BRICK MANUFACTURERS

D. Duddell Ltd.Fenton, Stoke-on-Trent

In the Potteries a favourite supplier of fireclay bricks was the firm of D. Duddell Ltd. Fenton.

http://www.thepotteries.org/brickworks/lane_end.htm

Sneyd Colliery Co. Ltd.

The Sneyd Colliery and Brickworks Company, Ltd.,

Nile Street, Burslem

|

| Fireclay brick used in the construction of the enamel kiln at Gladstone Pottery Museum Stoke-on-Trent. Used on the doors to the kiln. Makers mark impressed in the clay: SNEYD |

Harris and Pearson

South Staffordshire

http://www.harrisandpearson.info/index.html

E J and J Pearson

Fire Brick Works, Stourbridge, Worcs.

Founded 1860

Manufacturer of firebricks and fireclay goods at the Delph Works, Brierley Hill, which was their main centre of operation. They also owned the Crown Works, Amblecote; and Tintam Abbey Mines and Works at Brierley Hill. The combined output of these three sites in 1903 was around three-quarters of a million firebricks per week. The company also produced speciality bricks and tiles used in the construction of pottery kilns, glass house pots, gas retorts, crucibles, linings of blast furnaces etc.(Courtesy: Graces Guide https://www.gracesguide.co.uk/E._J._and_J._Pearson)

Berry Hill Brickworks Ltd

Berry Hill, Stoke-on-Trent

|

| Berry Hill Brickworks Advertisement 1960s |

Hall Brothers

(J. T. Hall Refractories)

Stourbridge.

Bonnybridge Silica and Fire Clay Co.,

Bonnybridge, (just north of Glasgow), Scotland

https://www.scottishbrickhistory.co.uk/bonnybridge-silica-and-fire-clay-co-bonnybridge/

John Stein

Castlecary Fireclay Works, Castlecary, Scotland

https://www.scottishbrickhistory.co.uk/john-gilchrist-stein-fire-bricks-of-great-importance/

| ||||

| Fireclay brick used in the construction of the enamel kiln at Moorland Pottery, Burslem. Used in the walls of the kiln. Maker's mark THISTLE impressed in the clay. John Stein, Castlecary Fireclay Works, Castlecary Photo: Terry Woolliscroft Collection Date: July 2019 Information courtesy: Mark Cranston www.scottishbrickhistory.co.uk |

BRICK SHAPES

To enable the complex shaping of both the hovel and the firing chamber a number of specially shaped bricks were used.| Tapered bricks used in bottle oven construction Gladstone Pottery Museum, Longton |

| Tapered and curved bricks used in bottle oven construction Gladstone Pottery Museum, Longton |

| Bull nosed bricks used in bottle oven construction Gladstone Pottery Museum, Longton |

|

| Some brick shapes |

BRICKWORKS and TILERIES in THE POTTERIES

According to Mr. Mort Brandon (via Phil Jenkins) on Facebook, the figure for the number of brickworks in the Potteries in 1875-76 was 122.The list below is courtesy http://www.thepotteries.org/brickworks/index.htm and shows 43.

- Acres Wood

- Adams, Tunstall

- Apedale

- Audley Brick & Pipe Co

- N Barlow

- Basford & Trent Vale Tileries

- Basin Brick & Tile Co

- Berry Hill Brickworks

- Berry Hill Collieries

- Bradwell Wood Tileries

- Brownhills Tileries

- Cannon Street Brickworks

- Cobridge Brick and Marl Co Ltd

- Cobridge Brick & Sanitary Pipe Co Ltd

- Cobridge Collieries

- Dalehall Brick & Tile Co

- Eastwood Brickworks

- Fenton Collieries

- Fenton Tileries

- W Ford

- Robert Heath & Sons Ltd

- J Hewitt & Son

- Highfield Tileries

- Lane End Works Ltd

- William Lea

- Lodge Tileries, Trent Vale

- Metallic Tileries

- Midland & Port Vale Tileries

- Mow Cop Brick Co Ltd

- J Noden & Co

- North Staffordshire Brick & Tile Co Ltd

- William Palmers

- Plant & Hammersley

- Rufus Brick & Tile Ltd

- Sneyd Colliery Co Ltd

- Stafford Coal & Iron Co

- Tunstall Tileries

- Walker

- Watkin

- Wheatly Brick & Tile Co

- Wigley & Shirley

- Wilkinson Brothers

- C Wooldridge

SOME CONSTRUCTION TERMINOLOGY

BATTERThe description of the slope given to the shape of the brickwork of the hovel of a bottle oven. Batters can be stepped or flat. Church batter is curved and real bottle shaped. Straight batter is truly conical.

BATTER RULE

BATTER RULE

Equipment. Used by a bottle oven builder as a measuring device. Used to give the required slope on the hovel. Sort of a protractor. (Source: Mountford, kiln builder)