"Tunstall, Burslem, Hanley, Stoke, Fenton, Longton, through the smoke"

Martin Chisholm for Picture Post, 2nd March 1946

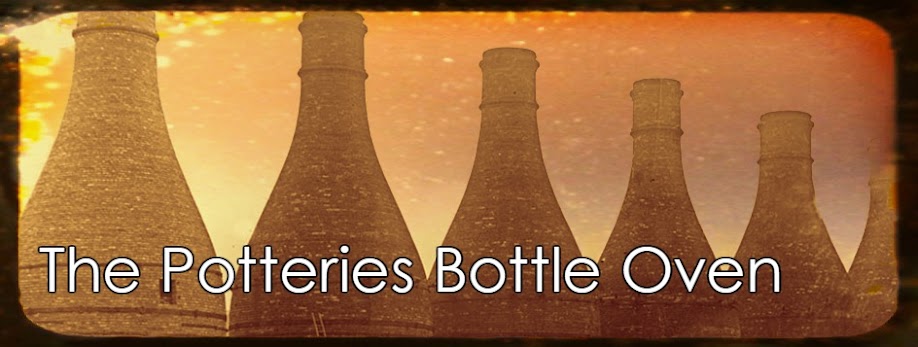

"The gaunt shapes of the 'bottle ovens' dominate the landscape of Stoke -on-Trent, Staffordshire. Here are made some of the most beautiful products of British Craftsmanship, Smoke blots out the sunlight; the craftsmen live in narrow streets, hemmed in by factories, some of them 175 years old. ... The whole atmosphere of Stoke-on-Trent and its surroundings tells you that it is a potter's world. And the symbol of it all is the kiln or 'oven', as it is called, which on every side, in twos or threes or larger groups, dominates the skyline, thrusting upward like a huge bottle of smoke-grimed bricks."

"This occasioned such immense and constant volumes of smoke, as literally to envelope the whole neighbourhood; and it was not infrequent for passengers to mistake their way, and run against each other, during the continuance of this process. The scene which presented itself upon these occasions, has been not inaptly compared to the emissions from Etna and Vesuvius..."

Monthly Magazine, 1st November 1823

"Figure to yourself a tract of country, the surface of which, cut, scarred, burnt and ploughed up in every direction, displays a heterogeneous mass of hovels and palaces, farmhouses and factories, chapels and churches, canals and coal pits, corn fields and brick-fields, gardens and furnaces, jumbled together in 'the most admirable disorder' and you will have a pretty correct idea of the Staffordshire Potteries. Pervade the space your fancy has thus pictured, with suffocating smoke, vomited forth incessantly from innumerable fires, and the thing will be complete."

| Longton and the Last Bottle Oven Firing in the Potteries Photo: Terry Woolliscroft Collection Date: August 1978 |

English Journey by J.B.Priestley, 1934

"There were no tall chimneys, no factory buildings frowning above the streets; but only a fantastic collection of narrow-necked jars or bottles peeping above the house tops on every side, looking as if giant biblical characters after a search for oil or wine, had popped them there, among the dwarf streets. These, of course, are the pottery kilns and ovens ... Without these great bottle of heat, there would be no Potteries. They represent a very heart and soul of the district, as you very soon learn; and unless you are prepared to take a deep and lasting interest in what happens inside those ovens, it would be better for you to take the first train anywhere."

THE CLEAN AIR ACT of 1956

Huge brick-built bottle ovens, integral to a pottery factory and essential in pottery manufacture, were once the dominant feature of the Potteries landscape. At their peak, in the 1930s, around 2,000 existed in the city of Stoke-on-Trent. Most of the potters' bottle ovens were fired once a week, some twice. At each firing at least 10 tons of coal was burnt in each oven. Some very large ovens, with up to 14 firemouths, used over 30 tons per firing. Each firing could last over 72 hours, sometimes longer in difficult conditions.But a change, initiated in the first quarter of the 20th century was building momentum as manufacturers searched for more efficient and cleaner ways to fire their products. Town gas, oil and electricity were taken on to fuel innovative intermittent and continuous firing tunnel kilns. The use of coal fired bottle ovens and kilns began to decline.

The Clean Air Act of 1956 finally put a stop to their use and sealed the fate of the traditional coal-fired oven. Pottery manufacturers were forced to change but allowed seven years to fully adapt to the alternative methods and fuels.

|

| Bottle ovens smoke Photo: unknown source Date: unknown |

THE ORIGIN OF SMOKE IN BAITING

Extract from: Excess Air in the Firing of Ovens and Kilns by J W Mellor, Based on a paper: Transactions of the English Ceramic Society, 6, 58, 1907"For the complete combustion of any fuel there must be an adequate supply of air intimately mixed with the combustible gases coming from the firemouths. The minimum volume of air required for the complete combustion of 1 lb. of carbon is nearly 143 cubic feet. This is the theoretical quantity deduced from the simple equation : C + O2 = CO2

But practically, owing to the fact that air and gas currents can pass along in streams side by side from firemouth to hovel without mixing to any great extent, very much more than the theoretical amount of air is required before we have an adequate supply for complete combustion.”

“I did not expect to find the greatest excess of air passing through the ovens and kilns immediately after a baiting when the fire-mouths were smoking, and least when the fire was burning clearly without smoke.

A probable explanation is that the burning hydrocarbon gases which are given off when coal is first put on the fire are decomposed by the inrush of cold air with the formation of smoke or soot, when the fireman opens everything immediately after a baiting in order to "clear the oven," and simultaneously the temperature is reduced below the "burning temperature" of the smoke.

The admission of cold air into a hot furnace burning hydrocarbon gases makes smoke instead of clearing it. But there are other reasons why air is allowed to rush through the oven immediately after a baiting.

The mechanism of the reactions which occur when the hot hydrocarbon gases, methane, ethylene and acetylene are brought in contact with cold air is, no doubt, a mechanism which is very complex. In any case the liberated carbon ultimately aggregates into particles of soot and smoke.

When smoke is once formed it can only be burned with very great difficulty.”

SUMMARY of the full article:

- In the firing of an ordinary kiln, with flues leading direct from firemouth to hovel, the flue gas has about 55 per cent, of air in excess of that theoretically required for the complete combustion of coal.

- The products of combustion enter the hovel at about 800° and therefore 4 cwts. of coal per ton are used in warming up the excess air passing through an ordinary kiln.

- The excess of air may be reduced about 85 per cent, by causing the flue gases to pass by a circuitous path from firemouth to hovel.

- There is over 50 per cent, excess air in the flue gas of an ordinary up-draught oven. This excess is reduced some 20 per cent, in firing down-draught.

- The practice of allowing an inrush of cold air immediately after a firemouth has been charged is mainly responsible for the formation of smoke and soot by the decomposition of the hot hydrocarbon gases. Note: Do not confuse soot with coal and ash dust.

~~~~~~~~~~

SMOKE CONSUMPTION IN THE POTTERIES

Extract from: The Civil Engineer and Architects Journal. Mention of The Sanitary Act 1866Here is an interesting piece about the smoky conditions of the Potteries. Digitised on Google Books click here>

|

| Burslem Alcock Lindley and Bloore on the corner of Overhouse Street and Scotia Road Photo: source unknown Date: unknown |

|

| Burslem T and R Boote, tile manufactures, Waterloo Road Photo: Source unknown Date: unknown |

| Middleport, Burslem Middleport Pottery - Oven smoking Photo: source unknown Date: unknown |

|

| Middleport, Burslem Middleport Pottery - baiting Photo: source unknown Date: unknown |

|

| Middleport, Burslem Middleport Burleigh Pottery Photo: source unknown Date: unknown |

Smoking bottle ovens in the Potteries

photo: taken at Earnshaw's potbank, Stoke-on-Trent

From the Gladstone Pottery Museum Photographic Collection.

|

| Hanley J & G Meakin Eastwood works from Lichfield Street Photo: source unknown Date: 1951 |

|

| Cliffe Vale, Hanley Twyfords Sanitaryware Factory Photo: courtesy EJD Warrillow Collection Date: 1951 |

|

| Longton Salisbury Crown China Works on the corner of Edensor Road and Stafford Street (The Strand) Photo: Source: Phil Rowley |

|

| Longton skyline Photo: source unknown Date: unknown |

|

| Longton Photo: Source unknown Date: Unknown |

| Longton The Last Bottle Oven Firing in the Potteries Date: August 1978 |

| Possibly Longton Photo: source unknown Date: unknown |

Peak District 1954

British Transport Films - extract

Begins with images of smoking bottle ovens.

Escape the smoggy city and join this colourful 1950s tour around

England's Peak District.

Robert Shaw provides the narration.

(from BFI Mediatheques around the UK - http://www.bfi.org.uk/mediatheque)